Every September all the OEMs, subcontractors and suppliers for the F-16 Fighting Falcon (pictured on the left) meet with the world’s F-16 Air Forces during a 3-day event in Ogden, Utah. This is the F-16 World-Wide Review (WWR). During this year’s F-16 WWR show about 200 companies had stands and presented their products and services for the F-16; there was also a wide range of contractor presentations about specific F-16 topics which all participants could attend.

Copernicus Technology Ltd (CTL) attended the F-16 WWR for the 3rd year in a row, working closely together with our USA partner, Universal Synaptics Corporation (USC). One of the highlights of the show was the presentation on the Intermittent Fault Detection and Isolation System (IFDIS) given by Ken Anderson, USC’s VP Business Development. A superbly delivered presentation, it generated a huge response and triggered a variety of Air Forces’ officials to visit the USC stand to explore how this revolutionary technology can be implemented. Of course, this was also the perfect opportunity to demonstrate how CTL can provide the same range of equipment sales and services to F-16 customers in the EU.

Every September all the OEMs, subcontractors and suppliers for the F-16 Fighting Falcon (pictured on the left) meet with the world’s F-16 Air Forces during a 3-day event in Ogden, Utah. This is the F-16 World-Wide Review (WWR). During this year’s F-16 WWR show about 200 companies had stands and presented their products and services for the F-16; there was also a wide range of contractor presentations about specific F-16 topics which all participants could attend.Copernicus Technology Ltd (CTL) attended the F-16 WWR for the 3rd year in a row, working closely together with our USA partner, Universal Synaptics Corporation (USC). One of the highlights of the show was the presentation on the Intermittent Fault Detection and Isolation System (IFDIS) given by Ken Anderson, USC’s VP Business Development. A superbly delivered presentation, it generated a huge response and triggered a variety of Air Forces’ officials to visit the USC stand to explore how this revolutionary technology can be implemented. Of course, this was also the perfect opportunity to demonstrate how CTL can provide the same range of equipment sales and services to F-16 customers in the EU.

Th e show also provided CTL with the perfect platform to launch new products in support of the Ncompass technology. Firstly there is our new Breakout Box (BoB) which is a huge aid to use of the Ncompass tester because it speeds up the process of building interface test adapters; not only that, the BoB can be used as an interface test adapter itself, for connecting other test equipment types (such as TDRs) to the ‘Unit Under Test’. The second new product on offer was CTL’s revolutionary software application, NODES (Ncompass Operator Data Entry/Evaluation System). NODES is another aid to augment the use of the Ncompass because it is used for compiling test files, managing test point data, managing results data and provides reporting for all aspects of the Ncompass’ testing function. CTL’s Sales & Marketing Director, John Schulmer (pictured above on the right, alongside CTL Technical Director Jim Cockram, on the left) concluded that “For Copernicus Technology Ltd this was another hugely successful show with new products launched, new contacts made and our excellent relationship with USC strengthened even further”.

e show also provided CTL with the perfect platform to launch new products in support of the Ncompass technology. Firstly there is our new Breakout Box (BoB) which is a huge aid to use of the Ncompass tester because it speeds up the process of building interface test adapters; not only that, the BoB can be used as an interface test adapter itself, for connecting other test equipment types (such as TDRs) to the ‘Unit Under Test’. The second new product on offer was CTL’s revolutionary software application, NODES (Ncompass Operator Data Entry/Evaluation System). NODES is another aid to augment the use of the Ncompass because it is used for compiling test files, managing test point data, managing results data and provides reporting for all aspects of the Ncompass’ testing function. CTL’s Sales & Marketing Director, John Schulmer (pictured above on the right, alongside CTL Technical Director Jim Cockram, on the left) concluded that “For Copernicus Technology Ltd this was another hugely successful show with new products launched, new contacts made and our excellent relationship with USC strengthened even further”.

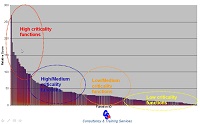

Ongoing collaboration between Jim Cockram of Copernicus Technology Ltd and CSA saw him deliver ‘Advanced Maintenance Strategy’ course in the Far East. Eleven Senior maintenance managers from a wide range of industry sectors were more than satisfied that the course aims, which included… to provide attendee with an array of tools that will help to drive down breakdowns at minimum cost while maintaining safety.. were met. The 3-day course proved to be very useful and well received in the setting of Malaysia’s capital Kuala Lumpur; comments included “excellent value for money”.

Ongoing collaboration between Jim Cockram of Copernicus Technology Ltd and CSA saw him deliver ‘Advanced Maintenance Strategy’ course in the Far East. Eleven Senior maintenance managers from a wide range of industry sectors were more than satisfied that the course aims, which included… to provide attendee with an array of tools that will help to drive down breakdowns at minimum cost while maintaining safety.. were met. The 3-day course proved to be very useful and well received in the setting of Malaysia’s capital Kuala Lumpur; comments included “excellent value for money”.

Behind the marketing glitz and glamour of this year’s F-16 World-Wide Review (WWR) (see ‘Meeting the International F-16 User Community’), Jim Cockram, Technical Director of Copernicus Technology Ltd (CTL), also used the opportunity to liaise with our friends at Universal Synaptics Corporation (USC) on a wide range of technical subjects. USC are the manufacturer of the revolutionary

Behind the marketing glitz and glamour of this year’s F-16 World-Wide Review (WWR) (see ‘Meeting the International F-16 User Community’), Jim Cockram, Technical Director of Copernicus Technology Ltd (CTL), also used the opportunity to liaise with our friends at Universal Synaptics Corporation (USC) on a wide range of technical subjects. USC are the manufacturer of the revolutionary  USC are based in Ogden in Utah, pictured on the left, which is the very town that hosts the annual F-16 WWR, so this was the perfect chance to catch up with them and to exchange and debate ideas and best practice. Jim Cockram had this to say about his technical liaison visit with USC:“CTL's visit to this year’s F-16 WWR was hugely informative and exhilarating from a technical point of view. We were exposed to USC’s plans for the further development of the ‘Super-IFDIS’ upgrades which will allow up to 40 Ncompass modules to be linked together to provide over 16,000 test points – all of which can be tested continuously and simultaneously! This step-change in testing capacity is a massive enhancement to an already outstanding testing capability, and serves to provide continuous and simultaneous testing on all the test points without any degradation in test coverage. The visit also allowed us to further strengthen our partnership with USC and to demonstrate NODES (Ncompass Operator Data Entry/Evaluation System) to them, which is our latest software innovation that allows users to capture, report and trend test results easily and quickly. In conclusion: an outstandingly hugely successful visit on all fronts”.

USC are based in Ogden in Utah, pictured on the left, which is the very town that hosts the annual F-16 WWR, so this was the perfect chance to catch up with them and to exchange and debate ideas and best practice. Jim Cockram had this to say about his technical liaison visit with USC:“CTL's visit to this year’s F-16 WWR was hugely informative and exhilarating from a technical point of view. We were exposed to USC’s plans for the further development of the ‘Super-IFDIS’ upgrades which will allow up to 40 Ncompass modules to be linked together to provide over 16,000 test points – all of which can be tested continuously and simultaneously! This step-change in testing capacity is a massive enhancement to an already outstanding testing capability, and serves to provide continuous and simultaneous testing on all the test points without any degradation in test coverage. The visit also allowed us to further strengthen our partnership with USC and to demonstrate NODES (Ncompass Operator Data Entry/Evaluation System) to them, which is our latest software innovation that allows users to capture, report and trend test results easily and quickly. In conclusion: an outstandingly hugely successful visit on all fronts”.

e show also provided CTL with the perfect platform to launch new products in support of the Ncompass technology. Firstly there is our new Breakout Box (BoB) which is a huge aid to use of the Ncompass tester because it speeds up the process of building interface test adapters; not only that, the BoB can be used as an interface test adapter itself, for connecting other test equipment types (such as TDRs) to the ‘Unit Under Test’. The second new product on offer was CTL’s revolutionary software application, NODES (Ncompass Operator Data Entry/Evaluation System). NODES is another aid to augment the use of the Ncompass because it is used for compiling test files, managing test point data, managing results data and provides reporting for all aspects of the Ncompass’ testing function. CTL’s Sales & Marketing Director, John Schulmer (pictured above on the right, alongside CTL Technical Director Jim Cockram, on the left) concluded that “For Copernicus Technology Ltd this was another hugely successful show with new products launched, new contacts made and our excellent relationship with USC strengthened even further”.

e show also provided CTL with the perfect platform to launch new products in support of the Ncompass technology. Firstly there is our new Breakout Box (BoB) which is a huge aid to use of the Ncompass tester because it speeds up the process of building interface test adapters; not only that, the BoB can be used as an interface test adapter itself, for connecting other test equipment types (such as TDRs) to the ‘Unit Under Test’. The second new product on offer was CTL’s revolutionary software application, NODES (Ncompass Operator Data Entry/Evaluation System). NODES is another aid to augment the use of the Ncompass because it is used for compiling test files, managing test point data, managing results data and provides reporting for all aspects of the Ncompass’ testing function. CTL’s Sales & Marketing Director, John Schulmer (pictured above on the right, alongside CTL Technical Director Jim Cockram, on the left) concluded that “For Copernicus Technology Ltd this was another hugely successful show with new products launched, new contacts made and our excellent relationship with USC strengthened even further”. Managing Director of Copernicus Technology Ltd (CTL), Giles Huby, presented CTL’s latest academic paper at the Royal Aeronautical Society's Airworthiness & Maintenance annual conference on the 16th Sept at Cranfield University, alongside fellow speakers including Mr Mick Adams (Maintenance Director of Monarch Air), Air-Vice Marshal Nick Kurth CBE (Senior Engineer Officer in the RAF’s Air Command) and Dr Bill Johnson of the FAA.

Managing Director of Copernicus Technology Ltd (CTL), Giles Huby, presented CTL’s latest academic paper at the Royal Aeronautical Society's Airworthiness & Maintenance annual conference on the 16th Sept at Cranfield University, alongside fellow speakers including Mr Mick Adams (Maintenance Director of Monarch Air), Air-Vice Marshal Nick Kurth CBE (Senior Engineer Officer in the RAF’s Air Command) and Dr Bill Johnson of the FAA.