The USAF is keeping F-16 ageing aircraft fleets flying and, at the same time, is saving money and keeping obsolescence at arm’s length. It sounds too good to be true, but this story continues to grow and grow every day at the 523rd Electronics Maintenance Squadron (Avionics) at Hill Air Force Base in Utah.

The USAF is keeping F-16 ageing aircraft fleets flying and, at the same time, is saving money and keeping obsolescence at arm’s length. It sounds too good to be true, but this story continues to grow and grow every day at the 523rd Electronics Maintenance Squadron (Avionics) at Hill Air Force Base in Utah.

The USAF is keeping F-16 ageing aircraft fleets flying and, at the same time, is saving money and keeping obsolescence at arm’s length. It sounds too good to be true, but this is story continues to grow and grow every day at the 523rd Electronics Maintenance Squadron (Avionics) at Hill Air Force Base in Utah.

"We had a large number of boxes, I would say 70-plus that found their way into a holding cell where they were tested by the Air Force technicians," said Chris Tatro, 523rd Electronics Maintenance Squadron (Radio Frequency Shop) electronics technician. "They threw every part at them they could, they did everything to their best knowledge, trying to troubleshoot them and found it had nothing to do with them - the box itself had those problems internally."

$2 million a year was devoted to maintenance of the AN/APG-68 Radar’s Modular Low Power Radio Frequency (MLPRF) units - including costs of as much as $30,000 for replacement ribbon cables. Consequently, the Base wanted to tackle the growing cost of these No Fault Found and Intermittent Fault problems and so they began looking for a solution….and they found it right on their doorstep: Universal Synaptics Corporation’s (USC) Intermittent Fault Detection (IFD) technology.

USC, manufacturers of the world-beating Ncompass IFD tester, in conjunction with TQS Inc, embarked on a joint venture to design and build an IFD and Isolation System (IFDIS) to test the rogue MLPRFs. The results are astonishing. "By early November, 171 MLPRF chassis have been tested, 131 of which had been considered un-repairable; 86 have been repaired and put back into service while the remaining IFDIS-diagnosed LRUs are awaiting repair parts," said Sami Mansour, 523 EMXS director. "The value of an MLPRF is over $307,000 each, so the 86 already recovered and returned to service represents a return of over $26 million…As a result, mean operating time between depot repairs for IFDIS-tested units has increased from 315 hours to 731 hours, a significant increase in support to the war-fighter directly attributable to the proactive depot actions.”.

But the last word on this goes to Chris Tatro. "It's fun to operate and to run," he says. "It gives me a sense of pride because it helps me help my fellow co-workers and tell them, 'You do this and it will be fixed.' There are some things that we just can't see and just can't do without this machine. It gives us X-ray vision in a sense."

You don’t have to go all the way to Utah for IFD and IFDIS solutions. They can be sourced directly in Europe from Copernicus Technology Ltd, exclusive distributor of USC test technology for the EU and Australian markets.

ntermittent Fault Detection was successfully selected as the clear winner of the US DoD’s 2010 Great Maintenance Ideas competition, beating over 300 other competitors in a vote of over 1500 senior DoD staff at their annual Maintenance Symposium in Tampa, Florida, on 15th Nov 2010. The top place was awarded in recognition of the Intermittent Fault Detection & Isolation System’s vast contribution to increasing F-16 avionics availability and reducing maintenance costs.

ntermittent Fault Detection was successfully selected as the clear winner of the US DoD’s 2010 Great Maintenance Ideas competition, beating over 300 other competitors in a vote of over 1500 senior DoD staff at their annual Maintenance Symposium in Tampa, Florida, on 15th Nov 2010. The top place was awarded in recognition of the Intermittent Fault Detection & Isolation System’s vast contribution to increasing F-16 avionics availability and reducing maintenance costs.

The USAF is keeping F-16 ageing aircraft fleets flying and, at the same time, is saving money and keeping obsolescence at arm’s length. It sounds too good to be true, but this story continues to grow and grow every day at the 523rd Electronics Maintenance Squadron (Avionics) at Hill Air Force Base in Utah.

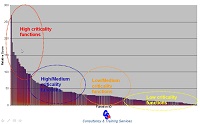

The USAF is keeping F-16 ageing aircraft fleets flying and, at the same time, is saving money and keeping obsolescence at arm’s length. It sounds too good to be true, but this story continues to grow and grow every day at the 523rd Electronics Maintenance Squadron (Avionics) at Hill Air Force Base in Utah. Ongoing collaboration between Jim Cockram of Copernicus Technology Ltd and CSA saw him deliver ‘Advanced Maintenance Strategy’ course in the Far East. Eleven Senior maintenance managers from a wide range of industry sectors were more than satisfied that the course aims, which included… to provide attendee with an array of tools that will help to drive down breakdowns at minimum cost while maintaining safety.. were met. The 3-day course proved to be very useful and well received in the setting of Malaysia’s capital Kuala Lumpur; comments included “excellent value for money”.

Ongoing collaboration between Jim Cockram of Copernicus Technology Ltd and CSA saw him deliver ‘Advanced Maintenance Strategy’ course in the Far East. Eleven Senior maintenance managers from a wide range of industry sectors were more than satisfied that the course aims, which included… to provide attendee with an array of tools that will help to drive down breakdowns at minimum cost while maintaining safety.. were met. The 3-day course proved to be very useful and well received in the setting of Malaysia’s capital Kuala Lumpur; comments included “excellent value for money”.

Behind the marketing glitz and glamour of this year’s F-16 World-Wide Review (WWR) (see ‘Meeting the International F-16 User Community’), Jim Cockram, Technical Director of Copernicus Technology Ltd (CTL), also used the opportunity to liaise with our friends at Universal Synaptics Corporation (USC) on a wide range of technical subjects. USC are the manufacturer of the revolutionary

Behind the marketing glitz and glamour of this year’s F-16 World-Wide Review (WWR) (see ‘Meeting the International F-16 User Community’), Jim Cockram, Technical Director of Copernicus Technology Ltd (CTL), also used the opportunity to liaise with our friends at Universal Synaptics Corporation (USC) on a wide range of technical subjects. USC are the manufacturer of the revolutionary  USC are based in Ogden in Utah, pictured on the left, which is the very town that hosts the annual F-16 WWR, so this was the perfect chance to catch up with them and to exchange and debate ideas and best practice. Jim Cockram had this to say about his technical liaison visit with USC:“CTL's visit to this year’s F-16 WWR was hugely informative and exhilarating from a technical point of view. We were exposed to USC’s plans for the further development of the ‘Super-IFDIS’ upgrades which will allow up to 40 Ncompass modules to be linked together to provide over 16,000 test points – all of which can be tested continuously and simultaneously! This step-change in testing capacity is a massive enhancement to an already outstanding testing capability, and serves to provide continuous and simultaneous testing on all the test points without any degradation in test coverage. The visit also allowed us to further strengthen our partnership with USC and to demonstrate NODES (Ncompass Operator Data Entry/Evaluation System) to them, which is our latest software innovation that allows users to capture, report and trend test results easily and quickly. In conclusion: an outstandingly hugely successful visit on all fronts”.

USC are based in Ogden in Utah, pictured on the left, which is the very town that hosts the annual F-16 WWR, so this was the perfect chance to catch up with them and to exchange and debate ideas and best practice. Jim Cockram had this to say about his technical liaison visit with USC:“CTL's visit to this year’s F-16 WWR was hugely informative and exhilarating from a technical point of view. We were exposed to USC’s plans for the further development of the ‘Super-IFDIS’ upgrades which will allow up to 40 Ncompass modules to be linked together to provide over 16,000 test points – all of which can be tested continuously and simultaneously! This step-change in testing capacity is a massive enhancement to an already outstanding testing capability, and serves to provide continuous and simultaneous testing on all the test points without any degradation in test coverage. The visit also allowed us to further strengthen our partnership with USC and to demonstrate NODES (Ncompass Operator Data Entry/Evaluation System) to them, which is our latest software innovation that allows users to capture, report and trend test results easily and quickly. In conclusion: an outstandingly hugely successful visit on all fronts”.